Digitisation & Industry 4.0

Brückner-ONE - unique in the BO industry

In Industry 4.0, production and state-of-the-art information and communication technology interlock. The driving force behind this development is the rapidly increasing digitisation of the economy and society. Production and logistics processes between companies in the same production process are intelligently linked to make production even more efficient and flexible.

Overall, the profitability of production can be increased, the competitiveness of industry strengthened and the flexibility of production raised.

What does that mean specifically for Brückner Maschinenbau?

In many places in the company, digitisation is being worked on. This influences our daily work as well as the further development of our products. SAP for order processing, CRM for customer management, engineering base in the cooperation between mechanics and electrics or EDI for the electronic order processing between us and suppliers are just a few internal tools with which we try to get complex contexts under control.

Decentralised Electrical Engineering / Intelligence, Machine Condition Monitoring (MCM), the increasing number of assistance systems for plant control and Easy Operation (EOP) can be cited as examples of our lines. The latter is part of our new "Brückner ONE" solution that is unique in the BO industry. "Brückner ONE" is a one-stop solution providing a digital platform supporting all matters of the line and its operation.

Currently, among others, we are working on:

- Line technology and customer requirements: decentralised intelligence (permit and ensure acceptance with dry running in pre-assembly).

- Supply chain from engineering to assembly: Automatic requirements planning based on scenario simulations as well as a digital identification number for all materials

- Continuous customer support via digital service platform with various modules such as remote platform, spare parts catalog and a service app. This is a part of the „Brückner ONE“ concept as well.

There is no way around digitisation. For the application to our own processes we pursue the strategy of the "fastest follower". With regard to our plant technology, we claim to be a trendsetter and to be ahead of our competitors. So we also consciously break new ground where necessary.

Easy Operation – Intelligent Line Management

Brückner's answer to Industrie 4.0

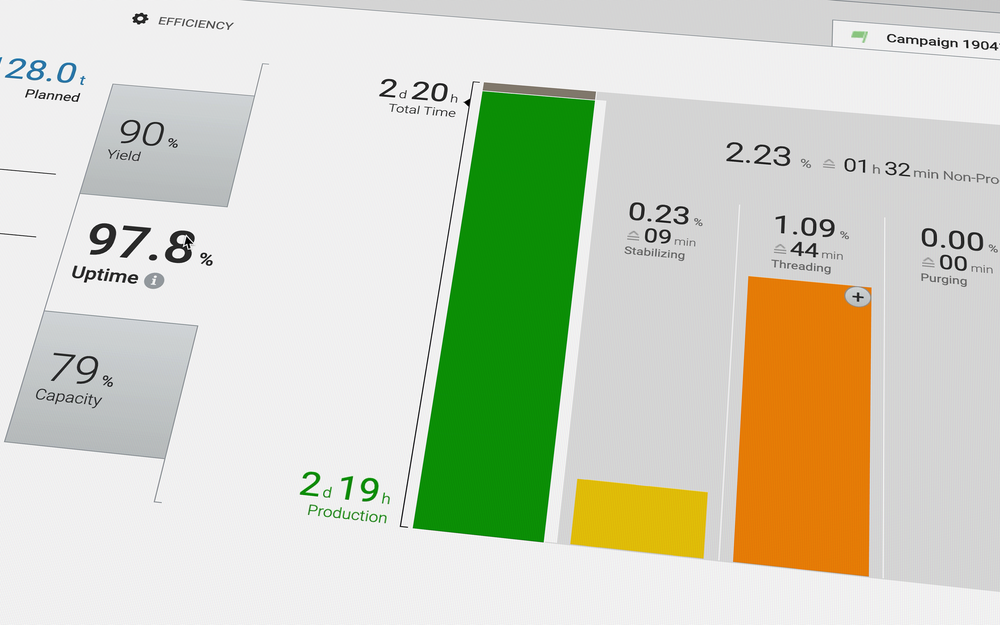

Brückner’s “Easy Operation” is a completely new, integrated solution, focusing on the process view as opposed to the usual machine view. At the same time the new operating concept offers guided operation by usage of assistants ensuring constant high efficiency and quality in film production.

Benefits

- Intuitive line operation with operator guidance and ease of use

- Fewer production parameters to adjust

- Transparency and traceability of production data

- Inline measurement of film properties for a consistently high film quality

- Increased line availability through shorter reaction time in case of malfunctions

- Efficiency and flexibility increase through assistant systems

Challenge

Continually increasing speed and output with ever shorter delivery times and production lots, but at the same time satisfying a growing demand for quality and product variety make running a film stretching line a highly complex business. Film producers and their operating personnel stand before increasing challenges when it comes to guaranteeing a stable and efficient production with the highest quality film.

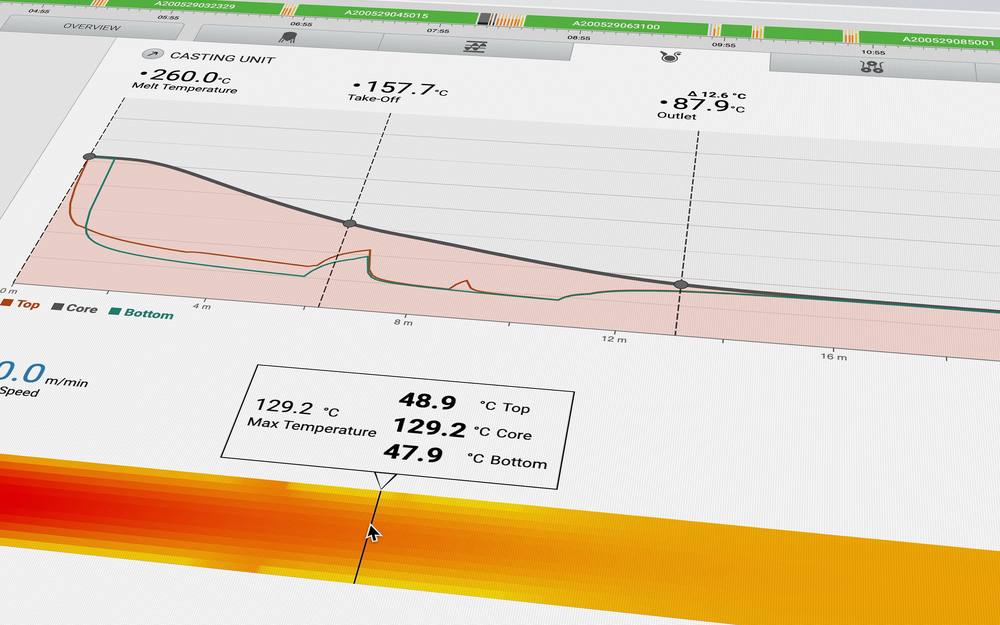

Process instead of machine control

The traditional means of control and still the standard today is the so-called machine control. The machine visualisation, used as front-end, represents details of sensors and actors. User interaction requires high skills and knowledge. For example, film temperature control is done indirectly, acting on air temperature and fan speed. Following the process control approach, the user will directly set the film temperature. The related machine parameter settings of air temperature and fan speed are calculated by a smart algorithm (patent pending).

Solution

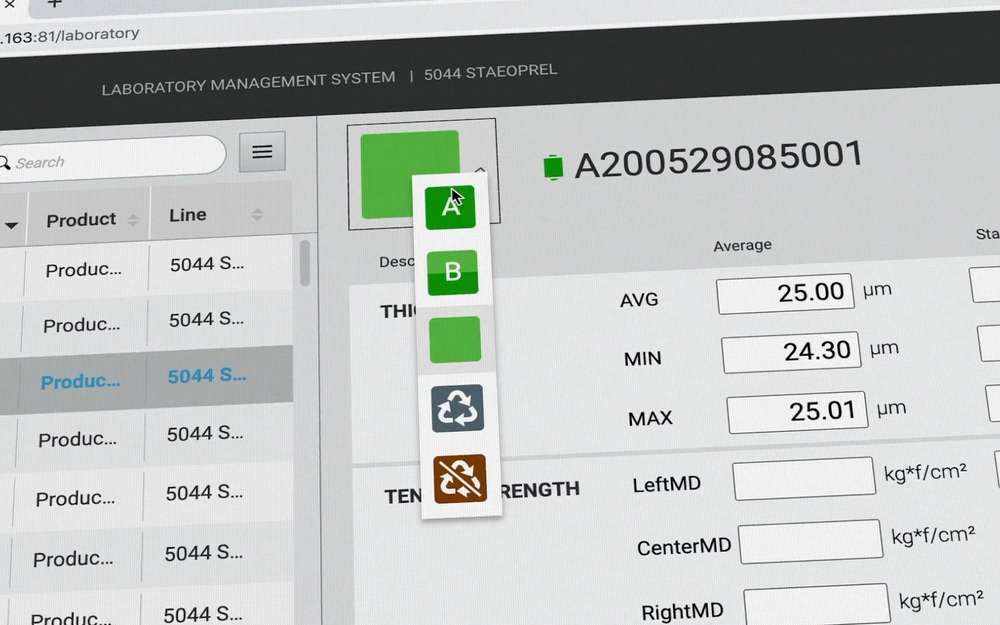

Brückner recognized this development at an early stage and created a new concept for operating stretching lines called – Easy Operation (EOP). This is a new integrated operating concept and part of the brand new digitalisation solution "Brückner ONE". As opposed to the usual machine parameter, the new operating concept for film stretching lines focuses on the process parameter.

Guided operation by usage of assistants

The efficiency of the production process and the obtained film quality depends on various factors, e.g. operator skills, shift, weekday. For critical, often performed activities, Brückner develops so-called assistants a spart of the new „Brückner ONE“ solution. The assistant provides comprehensive assistance with system operation and will guide the operator by means of predefined, customisable operating steps. The operating steps may follow, for example, the company standard procedure. Using an assistant the operator still maintains full control of the process. If required he may interfere manually at any time.

The advantage is clear: constant high efficiency and quality.