Technology Centers

Worldwide unique meeting point for R&D activities

Brückner's unique R&D environment includes our Innovation Test Center (ITC) as well as our Technology Center, both offering comprehensive R&D for all kinds of film stretching technologies under one roof. The Technology Center is rented to our customers and raw material suppliers for film and resin development.

Brückner Maschinenbau's unique technology centers

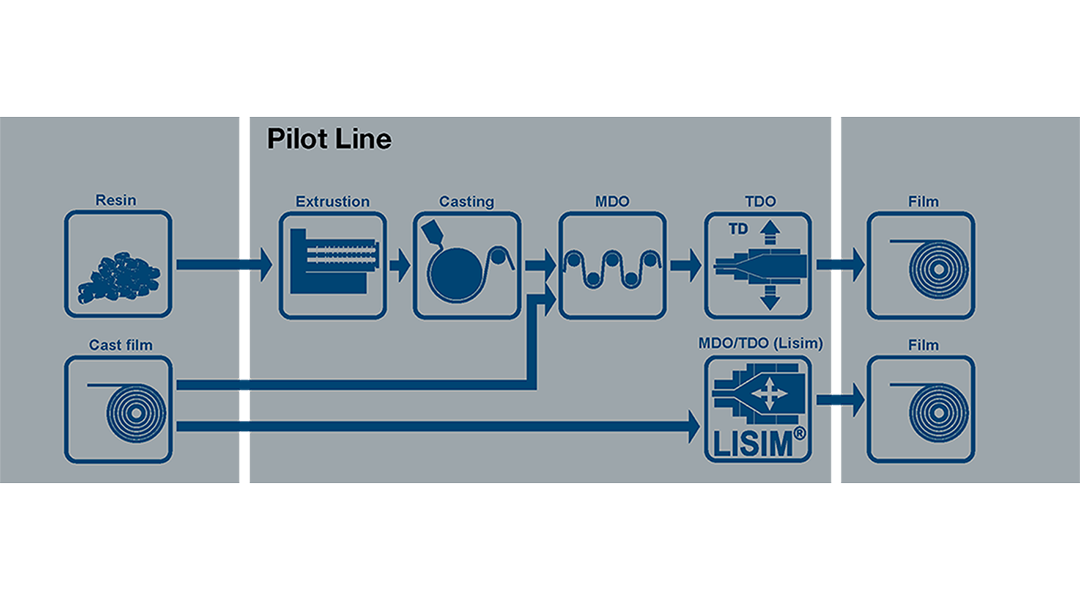

Pilot Line

Unique flexibility for all kinds of stretching

Brückner‘s Technology Center includes a uniquely flexibile pilot line. Numerous film types of up to 7 layers can be manufactured in all stretching modes:

- MD (machine direction) stretching for, e.g. tapes

- TD (transverse direction) stretching for, e.g. sleeves

- Biaxial sequential stretching for packaging and technical films

- Biaxial simultaneous stretching for specialty films (unique LISIM® technology)

The pilot line is the perfect environment for R&D and sample production for BOPP, BOPET, BOPA, BOPS, BOPLA, MOPET-G, MOPS and many other film types. Some of the highlights we produced on our pilot line:

Sequential BOPP 2 - 100 μm 1/3/5/7-layer

- Multifunctional packaging film

- Low sealing temperature for high speed packaging

- High sealing strength film

- High surface energy film

- Inline coated film

- Vacuum coated ultra high barrier film

- 7-layer high barrier film

- MD shrink label film

- Synthetic paper / Stone paper

Simultaneous

- Low thermal shrink BOPP

- High shrink cigarette packaging

- Roso-Film

- Thin capacitor film (< 3 μm)

Sequential and Simultaneous BOPET 2 - 400 μm 1/3/5-layer

- Heat sealable film (lidding for plain PET trays)

- Inline coated film (chemically treated)

- Thick film (basics for optical grade)

- Solar backsheet (UV stabilized)

- Low shrink film (substrate for flexible electronics)

- Low MOA film (polarizer protection)

- Ultra thin capacitor film

Sequential and Simultaneous BOPA 15 - 35 μm 3/5-layer

- Low shrink film

- 5-layer high barrier film

- Cold forming film for blister & battery pouches

Sequential BOPE 15 - 50 μm 3/5-layer

- Thin and tough sealing layer

- Display shrink film

Battery Separator Film 5 - 25 μm 1-layer

- PE-Evapore® UHMWPE and HDPE

Monoaxially oriented film: PETG, PS, Polyolefin 30 - 50 μm 1/3/5-layer

- MD oriented shrink sleeves

- TD oriented shrink sleeves

And others: BOPLA, BOCOC, BOPVDF, BOPEN, BOPEEK, BOPC, BOPVA

Perfect for R&D

and sample production for many film types

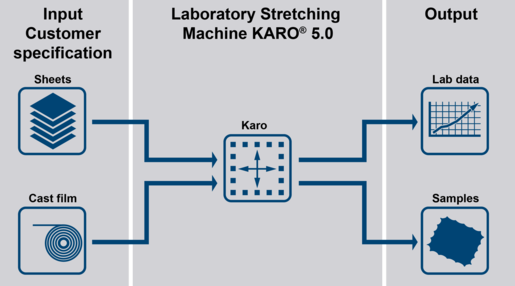

Laboratory Stretching Machine KARO® 5.0

Test films and sheets in a very simple and economical manner

With our laboratory stretching machine KARO® 5.0 for monoaxial and biaxial film orientation it is possible to test films and sheets in a very simple and economical manner – in the sequential as well as in the simultaneous stretching mode.

It is ready for your use and can be rented on an hourly cost basis:

- Development of new film recipes and materials

- Test of new skin layers / additives

- Identification of process conditions

- Generation of stress strain curves

- Evaluation of film properties from stretched samples

- Quality insurance for raw materials

- Small batch production

Highlights & benefits

-

Newly designed user interface – intuitive & easy machine control

-

Accurate, reliable film temperatures by circulating air ovens – homogenious film samples

-

Improved insulation and temperature separation – Perfect process control by accurate temperature balance, stable film quality

-

Good accessibility – for easy maintenance, less downtime

-

Moving stretching system through different temperature zones – the same as on film stretching lines conditions close to film production line

Laboratory Stretching Machine KARO® 5.0

Watch this video to get a quick overview

You want to know more about our labstretcher KARO® 5.0?

Watch this video to get some detailed information

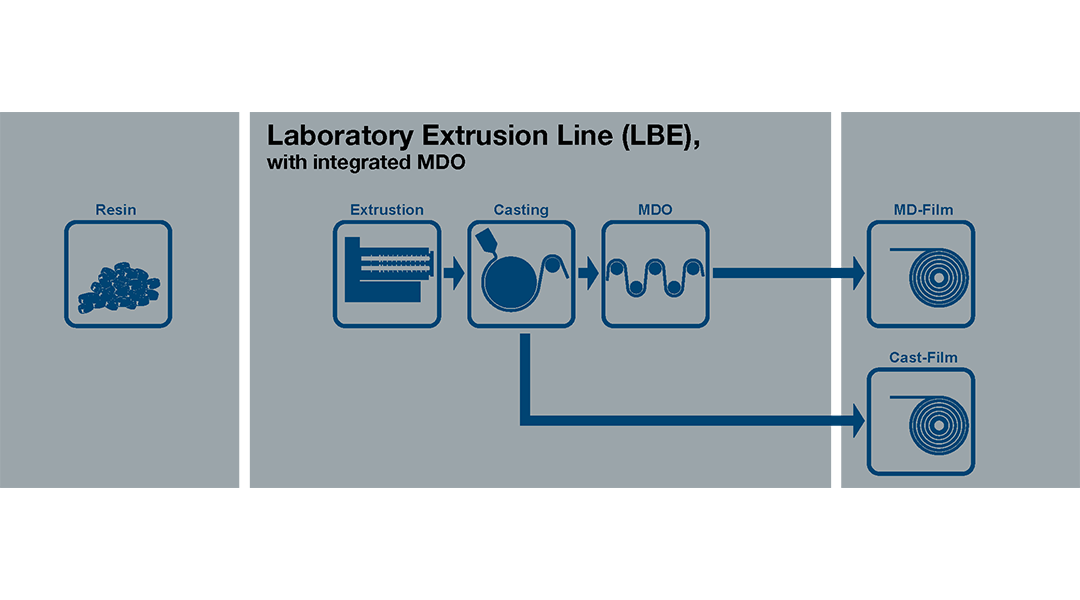

Laboratory Extrusion Line

Multi-layer film extrusion for various film types

For the development of new film formulations or new film types, Brückner Maschinenbau has installed a laboratory extrusion line (LBE) with the following features:

- Three twin-screw extruders and one single-screw extruder

- Granulate, powder and liquid dosing e.g. for process development by BSF

- Wide slit die and multilayer feedblock for the extrusion of single- or multi-layer cast film (up to 3-layers in any combination)

- MDO - for the stretching of the cast film in the machine direction

Four different investigation strategies are possible:

- Production of a cast film for the investigation of stretchability on the laboratory stretching machine KARO® 5.0

- Production of a cast film for the investigation of the simultaneous stretching process in the roll-to-roll process on the pilot line

- Production of a cast film and stretching in machine direction (MD) on the LBE and then in transverse direction on KARO® 5.0

- Process development extrusion

Chemical & Film Laboratory

We can (almost) do everything

- Analysis of film, raw materials and components

- Support from start to finish – lab equipment, on-site training, trouble shooting

- Lab equipment from manufacturers we trust

- On-site training for your staff by our experienced lab specialists

- Trouble shooting and support to quickly find a solution for your problem

- Film produced on our pilot line, the lab stretcher KARO® 5.0 or the LBE line can be examined immediately by our skilled personnel

- Special equipment available - such as REM, laser scanning microscope and birefringency measurement

- Long term measurements of film samples

- State-of-the-art – we are continually updating and upgrading our testing devices and methods

- In-house development of test methods to suit your requirements

- Analysis of battery separator films – gurley, pore size, continuous thickness measurement

Innovation Test Center (ITC)

All our technical improvements are rigorously tested

Our “Innovation Test Center” is an important part of the professional development process at Brückner Maschinenbau for a number of reasons: We aim to offer our customers proven film stretching line solutions that are absolutely reliable. This also applies in the case of completely new innovative projects even if they are being used in production for the very first time.

We prove our expertise in advance through experiments and measurements on several testing devices:

High-speed clip and track test stands in production environment

- Feasibility of speed increase under simulated production conditions: high speed roller chain and sliding chain

- Optimisation of all with the main focus on reducing lubrication, friction and temperatures

-

Further development with the objective of robustness and long service life

Oven test bed and nozzle boxes

- Further development of new oven nozzles and other concepts

- Analysis of air distribution and temperature homogenity

-

Further development of energy-saving insulation

Nip roll test stand

- Testing of new roller surfaces

Pinning test stand

- Optimisation of the pinning function to increase speed