We guarantee your success

Long-term thinking – the key to success in the world of oriented films

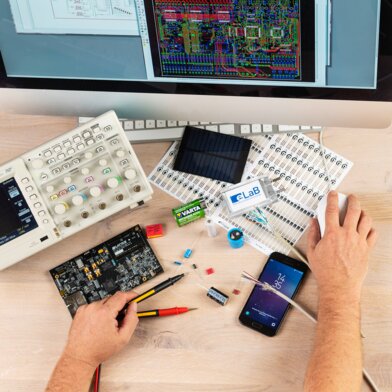

We offer innovative technologies and services for your industry. Providing the widest film stretching lines with the highest output and the lowest production costs, we still remain flexible in order to allow the production of a variety of films.

Our innovations and experience enable us to supply solutions that will serve film producers‘ needs better in various markets – whether in the cost-competitive commodity business or in the technologically advanced specialty film markets.

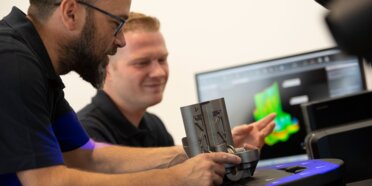

Our cutting edge film stretching innovations for a wide variety of films have gained worldwide reputation within the technical film markets. Numerous key players have already chosen our advanced solutions. As market leader in terms of film stretching we understand the market demands for both an outstanding film quality and also for a highly productive, efficient and flexible manufacturing process.