Reduction of sharkskin effect on Battery Separator Film

This article summarizes the results of our tests

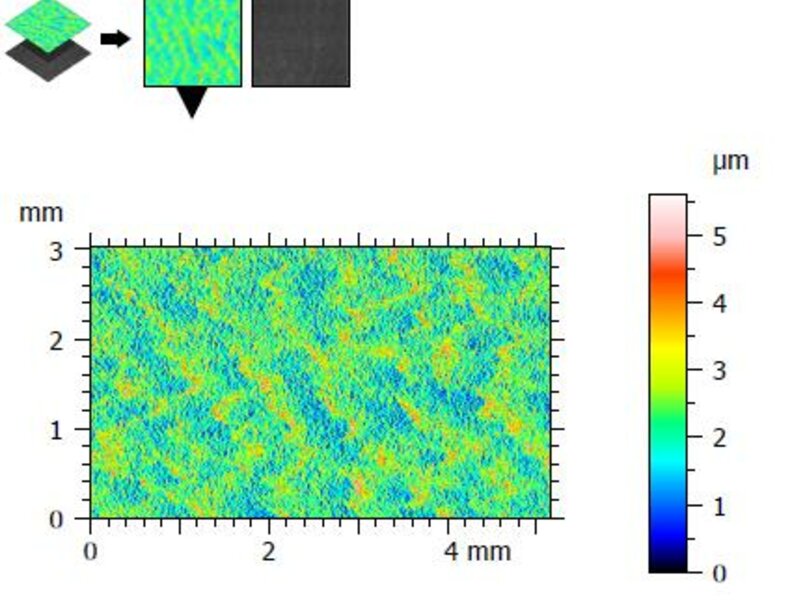

Sharkskin is a widespread and known melt defect that appears at the die exit. The place of origin need not necessarily be the die or the die outlet. Frequently, the causes are also found in the plasticization of the extruder or the melt guidance.

In general there are several ways to avoid or reduce sharkskin.