KARO® 5.0: A cutting-edge technology for testing films and sheets

22 May 2024

Users praise the benefits for their business

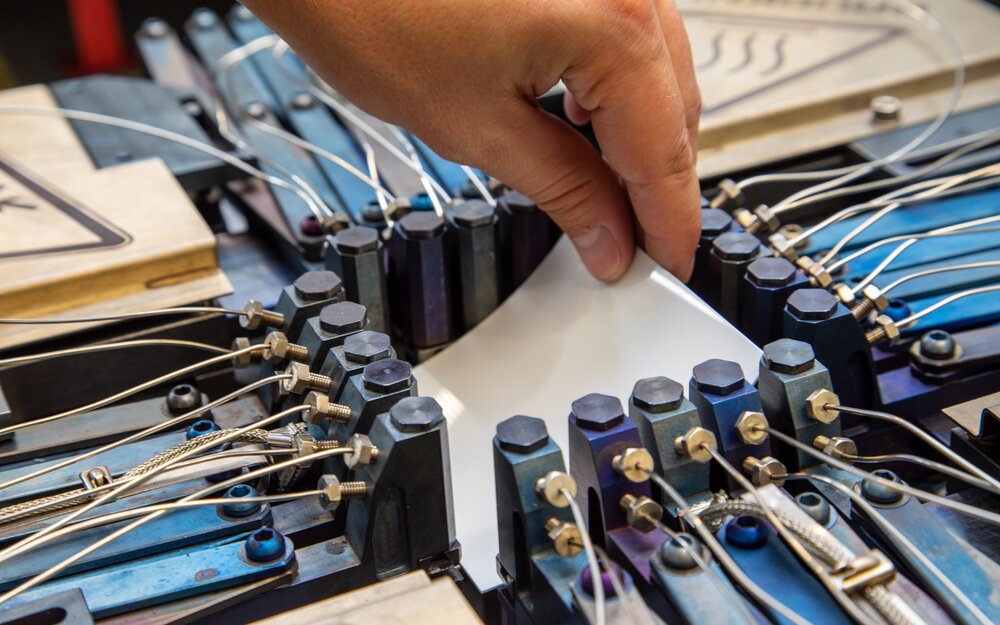

With Brückner’s laboratory stretching machine KARO® 5.0 for monoaxial and biaxial film orientation it is possible to test films and sheets in a very simple and economical manner – in the sequential as well as in the simultaneous stretching mode. Since many years it has been an integral part of the company's own technology center and can be rented on an hourly cost basis – and this offer is very well utilised in the industry.

Even more, several companies along the value chain for plastic film and packaging decided to acquire their own KARO® 5.0. Universities and research institutes, raw material suppliers or film producers worldwide profit of the various features to

- Develop new film recipes and materials

- Identify process conditions

- Evaluate film properties from stretched samples

- Ensure raw material quality

- Produce small batches

Recently, LyondellBasell – a leader in the global chemical as well as in polyolefin technologies and one of the world’s largest producers of polymers – expressed their excitement when adding a KARO® 5.0 to their research and development capabilities at the Technical Center in Akron, Ohio.

According to their own press release they are now they able to

- Troubleshoot and test masterbatch solutions for diverse oriented film applications with greater accuracy and efficiency

- Create a closer match to masterbatch materials in real-world production processes, significantly reducing the time it takes to bring new products to market

- Improve the speed-to-market process by allowing customers to quickly identify and select the optimal masterbatch for their specific needs

Chuck Hampton, LyondellBasell’s director of Masterbatch and Colors U.S. & Canada, states that “the addition of the KARO® 5.0 reinforces our technical leadership and commitment to innovation in the masterbatch industry” and mentions the lab stretcher’s cutting-edge features, including:

- Multi-cast film capabilities that enable the testing of a wider range of masterbatch materials

- Stretch capabilities in both the machine direction (MD) and transverse direction (TD) to accurately simulate real-world production conditions

- Monitoring of various material characteristics like tension, elongation, torque, temperature, and thickness to ensure optimal performance and quality control

And a very renowned specialty film producer and long-term Brückner customer, who does not want to be named, says in response to the question “are you satisfied with your KARO® 5.0 ?”: „Yes. Everyone is happy with our new machine – very aesthetically beautiful and capable.” A Korean customer even says”… we are still falling in love with KARO 5 “

Get more information here Technology Center and get a closer look at KARO® 5.0 here: Brückner´s KARO 5.0

To agree on trials please contact thomas.haberlander@brueckner.com

To integrate a KARO® 5.0 into your R&D environment please contact boris.pasternak@brueckner.com