BOPE Packaging Solutions

The Next Step Towards a Circular Economy

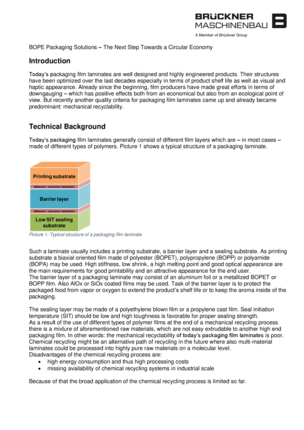

Today’s packaging film laminates are well designed and highly engineered products. Their structures have been optimized over the last decades especially in terms of product shelf life as well as visual and haptic appearance. Already since the beginning, film producers have made great efforts in terms of downgauging – which has positive effects both from an economical but also from an ecological point of view. But recently another quality criteria for packaging film laminates came up and already became predominant: mechanical recyclability.