Working on the future for BOPE mono-material solutions

29 Mär 2023

JK Materials convinces with new films and applications

The family-owned Korean flexible packaging film producer JK Materials manufactures and distributes BOPP, BOPA and LLDPE films – the latter already since 1974. With this background of experience, it was obvious to look more closely at trendsetting BOPE mono-materials. And it was also obvious, to take a closer look at the new hybrid line concepts of long-term partner Brückner Maschinenbau.

Jay Lee, Business Dept. General Manager of JK Materials says: “Many brand owners and converters show great interest in recyclable packaging – and so in BOPE. Since the start of our Brückner line last year we have already initiated a number of projects in Japan and Korea with both and also with retailers. We are sure that BOPE will be a game changer in the packaging world.”

Notable examples of BOPE adoption include a famous F&B maker using BOPE (HDPE) for mono-material pouches and a pet food maker switching cat litter pouches to BOPE films. JK Materials is also collaborating with multiple converters on various projects to create mono-material pouches for general purposes and those with barrier functions. Additionally, the company has started producing BOPE (LLDPE) for protective film applications.

JK Materials has the prerequisites to be a trendsetter in this field with its new Brückner BOPP/BOPE hybrid line. The 6.6m line produces up to 25.000 tons of BOPP and BOPE HD and LLD films in a thickness range between 12 and 60 µm per year. Production efficiency is guaranteed, among other things, by a special screw geometry and casting unit design.

JK Materials’ President Soo-Jung Hahm: “We are very happy that Brückner together with our engineers recently completed all line guarantee runs at our site in Dangjin. For us now is the perfect time to produce high quality BOPE film on a commercial scale. We at JK Materials clearly see a paradigm change in the plastic packaging industry – and we are ready for it with new mono-material solutions. I really look forward to continuing our cooperations with PE resin suppliers and multinational packaging companies in terms of recycling, circular economy and sustainability.”

Out of the aforementioned cooperations and a lot of own R&D, JK Materials has developed some really interesting pouch applications which have caused a stir in the market. Boris Pasternack, Sales Manager at Brückner Maschinenbau, sees a lot of potential: “The samples are convincing and JK Materials’ good reputation in the industry also ensures that attention is paid along the value chain.”

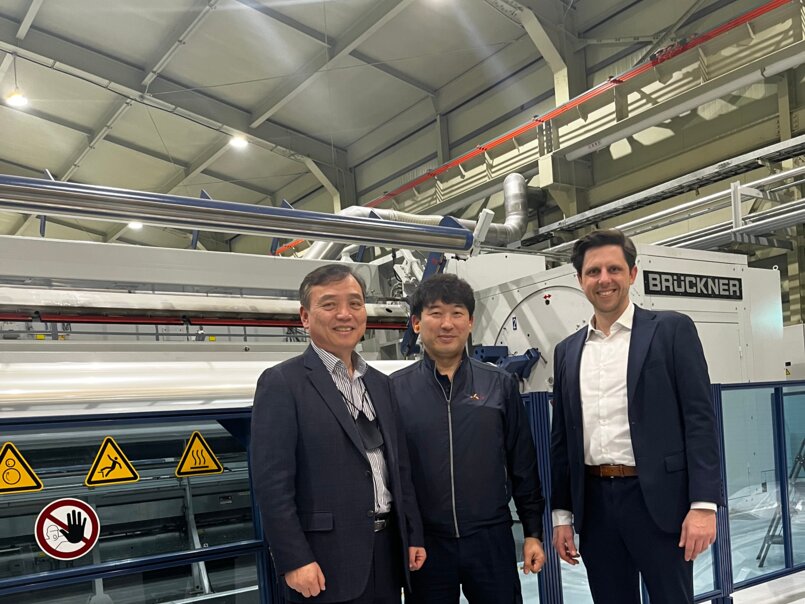

Pic caption (from left to right): Soo-Jung Hahm, President, Oh Jungwook, Shiftleader, both JK Materials, Boris Pasternack, Sales Manager Brückner Maschinenbau