Composite current collector films on the rise

04 Dez 2023

A new technology improving battery safety and increasing power density.

Lithium-ion batteries are the state-of-the-art power source for various applications, ranging from consumer electronics to electromobility. Current collectors are an indispensable part that bridges lithium-ion batteries and external circuits, greatly influencing the capacity, rate capability and long-term stability of lithium-ion batteries. Conventional current collectors work with aluminum and copper foils and have been in use since the first commercial lithium-ion battery. However, in order to improve safety, reduce weight, enhance energy density, and reduce costs – in summary, to further enhance the performance – alternative materials are needed for next-generation lithium-ion batteries providing a higher capacity and longer service life.

A promising approach: composite current collectors

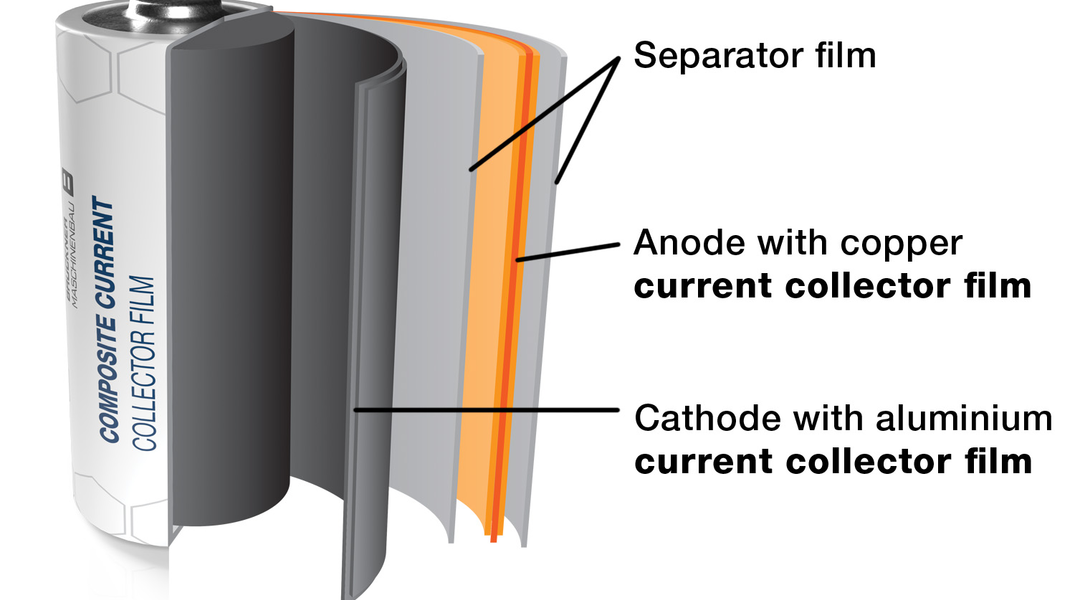

In contrast to a traditional current collector, the composite current collector incorporates the "metal-polymer-metal" three-layer composite structure, and forms thin-scale metal on the surface of a biaxially oriented film substrate (either PP or PET) by metallization process, magnetron sputtering, etc. This is an important aspect in line with the trend of making current collectors lighter and thinner and eventually increasing the energy density of power batteries.

And composite current collector films have multiple benefits:

- higher safety due to the strong puncture resistance of the polymer

- if damaged, e.g. by nail penetration, the composite current collector acts like a fuse preventing the resulting thermal runaway and spontaneous combustion of the battery

- increase of energy density (up to 10%) due to ultra-thin composite current collectors

- outstanding thermal stability

- perfect flatness for consecutive converting processes

- reduced costs by saving up to 66% on copper and up to 85% on aluminum

- compared with conventional Cu and Al collectors, a composite current collector saves significant amounts of CO2 emissions (due to savings in copper and aluminum production)

Most certainly, biaxial stretching technology has proven to be the best when it comes to the ideal composite current collector film. No matter whether a film manufacturer wants to use the sequential or simultaneous stretching process – Brückner Maschinenbau offers both proven technologies.

At the company’s Technology Center, several insiders have already tested various formulations and stretching methods to identify the best process window and film properties. As a proof of concept, Asian film manufacturers with the appropriate know-how in the downstream processes have already ordered Brückner lines – sequential as well as simultaneous ones – to meet these future market demands.