Sustainability is important to us

We are aware of our responsibility

One of our main concerns is to leave the best possible world for future generations. Brückner Maschinenbau is therefore working on processes to be able to produce films on our machines with the lowest possible use of resources and the highest possible recyclability.

The plastic films produced on Brückner equipment reliably protect packaged foodstuffs against environmental influences, for example. This extends their shelf life and reduces food losses.

At the same time, the Brückner Group is aware of its responsibility with regard to the environment and sustainability. That is why the initiative "Yes, we care" was launched in 2017. Because: Environmental protection starts in your own company!

Sustainability Report of the Brückner Group

Further sustainable initiatives

We take care about sustainable film production and participate in different initiatives

可持续性发展计划的成员

我们致力于为后代创造一个美丽的家园

R-回收循环

R-回收循环是一个开放的、全球通用的塑料包装整个生命周期跟踪标准。 总体目标是实施一个切实可行的解决方案,通过基于既有技术对所有与回收相关的包装特性进行无缝记录,从而确保可回收性。 因此,在回收过程中,可以准确识别包装,以便将回收物加工成各种高质量的塑料制品。

在与包装制造商,品牌所有者,批发商和零售商合作,引入全球标识编号,并开发物联网网关,必要的服务器架构和用于安全数据交换的标准化格式。 该项目的合作伙伴包括:阿博格,考特斯机械制造有限公司,莱芬豪舍,EREMA, Kampf, STEINERT, MULTIVAC, 布鲁克纳机械有限公司,塑料加工研究所(IKV)和德国GS1。

PRINTCYC

2019年3月,有一群公司发起了一个名为PRINTCYC(机械回收PP印刷薄膜)的价值链项目,研究和测试如何根据后工业废料创建循环经济解决方案。 PRINTCYC的成员:机器供应商包括布鲁克纳机械有限公司,凯孚尔公司和PackSys全球,薄膜生产商Profol,油墨制造商Huber Group和盛威科(Siegwerk),后加工商Constantia Flexibles和Wipak以及回收专家奥地利埃玛。

该计划由akk Innovation协调,该公司是一家独立的初创公司,致力于塑料包装行业的可持续创新管理。 前两个项目阶段的具体目标是了解不同油墨配方对加工PP和PE回收过程的影响。 此外,在流延膜,吹膜,模压成型和热成型以及双向拉伸工艺方面对印刷后工业膜废料制成的PP和PE回收物(rPP / rPE)的再利用性进行了评估。 现在,该团队正在联系新的潜在价值链合作伙伴和其他回收计划,以设计下一个工作包,以促进印刷PP和PE薄膜的循环经济。

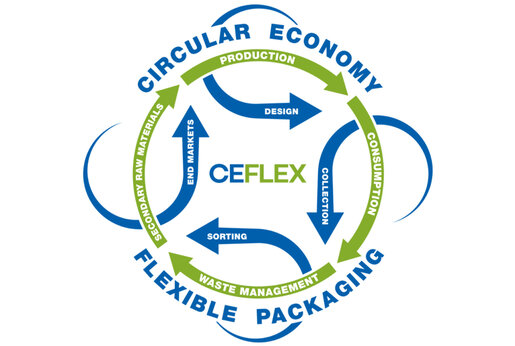

CEFLEX

软包装循环经济

迈向循环经济

我们责无旁贷

我们视保护珍贵资源为己任。因此我们参与了由整个软包装(CEFLEX)价值链上的公司和协会所组成的欧洲联盟的合作项目。

该项目旨在使软包装更加符合循环经济。通过与代表整个价值链的公司合作,推进更好的系统设计解决方案来实现这一目标。

CEFLEX愿景

- 至2020年,欧洲大多数国家使用的软包装将是可回收包装

- 至2025年,建成一个收集、分拣和再加工的基础设施/经济,用于处理欧洲各地消费后的软包装。

Blue Competence

Blue Competence为机械工程行业在可持续性领域建立了联络网,并汇聚了欧洲最大的工程行业网络 — 德国工程联合会(VDMA)的资源、技术和优势。

蓝色能效(Blue Competence)— 展示机械与设备工程领域的技术和工艺,例如在提供最大生产力的同时,消耗最少的能源,保护资源,最大程度地减少排放或持续改善人们的生活条件。

每一个VDMA成员公司在签署了Blue Competence品牌使用协议后,都可以参加Blue Competence的倡议活动,并有义务在互联网上发布机械工程的12项可持续发展标准。

蓝色能效(Blue Competence)如何促进世界的可持续发展

成员公司针对当前的关键性问题发表各自的见解和解决方案,并通过有效的沟通措施取得所有成员及各专业协会的配合与支持。为此,蓝色能效制定了可持续性的标准,所有参与该倡议的公司均通过背书的方式认可这些标准。该倡议可确保更高的透明度,简化了培训,并为所有寻求可持续解决方案、产品或可持续经营的公司提供保障。

VDMA在www.bluecompetence.net上发布了各专业协会和协会成员公司的详细信息,“最佳实践案例”,以及对可持续业务、生态和社会解决方案的实施具有重要意义的观点和立场。