A Time For Celebration

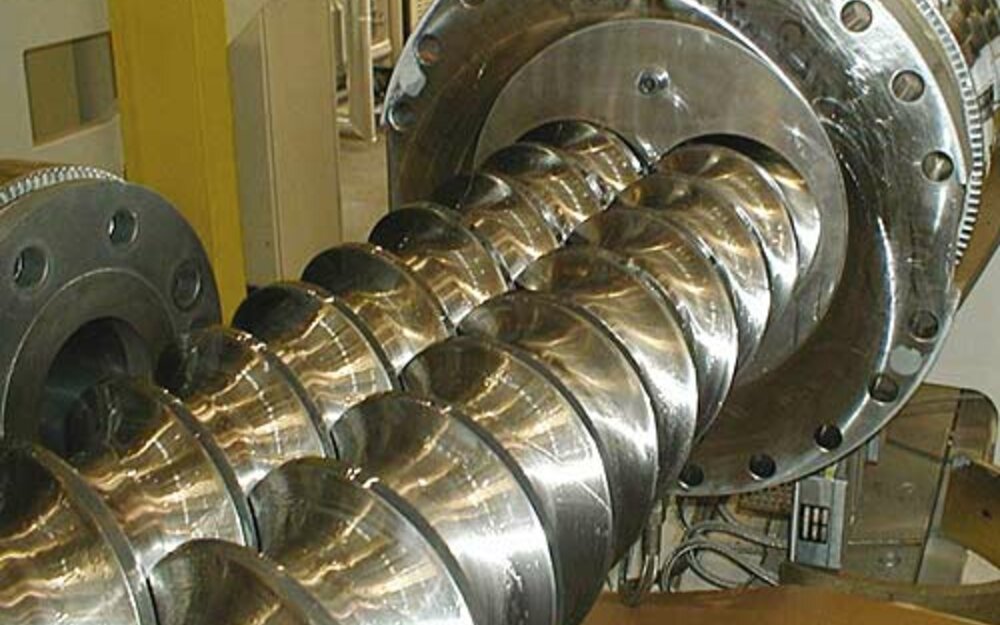

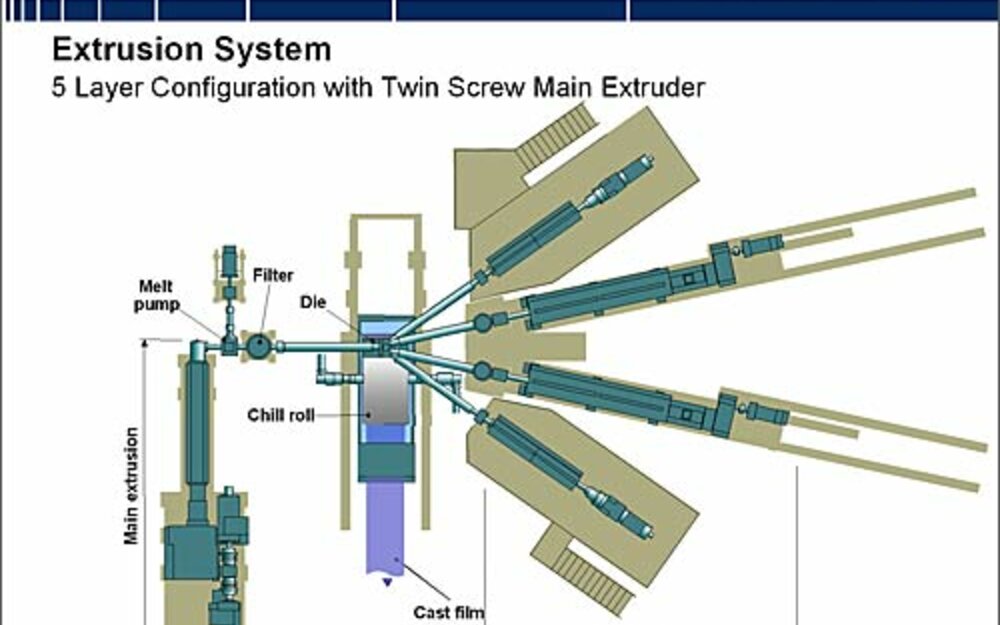

Ten years ago, in 1996, Spanish film producer Polipropileno de Galicia, S.A. (Poligal) and Brückner - sharing a mutual vision - decided to embark on a common path and join forces for a special project. This farsighted decision paved the way for the breakthrough of a revolutionary technology for film stretching lines. For the first time ever, a BOPP film production line was equipped with a twin screw extrusion system. Brückner’s trend-setting development included a number of absolute novelties, such as a unique raw material feeding system or a special twin screw software. Both of which were specifically designed for this application.

Brückner had started first trials implementing this twin screw technology on their very own laboratory line in the early 1990s. When it was ready to be brought to market, the courage to try something completely new - backed by the steadfast co-operation between Poligal, Brückner and several sub-suppliers - paid off immensely: Poligal’s line has been running smoothly and producing high-class BOPP film ever since. The company thereby has been benefiting from several twin screw achievements:

Excellent melt homogenization and targeted influence on melt temperature

Stable production and high operational availability, independent from variable raw material qualities

Low energy consumption

Widest flexibility regarding product changes

Very high wear/tear resistance

Compact machine design thus requiring less space

Production of high quality pearlized and white opaque film

Self-cleaning effect

Melt free of gels and volatiles due to degassing

Yet another benefit is the highly improved melt homogenization and color dispersion when coloring via master batches.

In the words of Jose Luis Doldán A., Poligal’s technical director: “Thanks to the technical advantages of the twin screw extrusion system, we were able to obtain a much better melt quality. This factor has been a key point to reach an excellent film quality with high production efficiency. Due to Poligal’s decision to be the first film producer to install a twin screw extrusion system, the company has become one of the most important market suppliers of thin and cavitated BOPP films.

In summary, we should point out that our cooperation with Brückner in this project gave us the chance to develop from a small volume producer to one of the best known quality leaders in the worldwide BOPP market.”

Continuing twin screw development

Starting with this successful first implementation, twin screw technology has now become state-of-the-art for stretching lines, assuring efficient, flexible and reliable film production, not only using PP, but increasingly also PET, PA or PS and other polymers. Additional applications, e.g. value-added PE-PA laminates are possible when paired with Brückner’s LISIM® technology. Today, the vast majority of Brückner lines sold use a twin screw system.

Over the years the twin screw benefits have been constantly improved by Brückner:

Increased automation level ensures absolute comfortable line operation

Spheripol processing possible (no granulation necessary)

Constant reduction of wear and tear

Enhanced process stability

In co-operation with leading extruder manufacturers Brückner aims to achieve smaller screw diameters and higher outputs of up to 7,000 kg/hour in order to further optimize the technology’s cost/performance ratio.

Another aim is offering our partners the highest possible level of flexibility: The size of batches and lots will continue to decrease, following market demand for just-in-time deliveries. This in turn means that extrusion systems and resin feeding must be highly flexible to guarantee very short and efficient product change-over times.

Last but not least: Reducing energy consumption/use will continue to be a prime target with special emphasis on lowering energy losses, as well as systems that combine shop floor heat and power in order to regenerate this by-product and convert it into electrical supply.

Brückner will carry on their research and development in this area, as well as in many other fields. Not only for the sake of maintaining their position as an innovative market-leader, but also to ensure that they continue to be a reliable partner to the producers of oriented film, while at the same time supplying them with ground-breaking technology to help sharpen their competitive edge.